Efficiency in Garment Manufacturing: Cutting

From knitting to cutting, the company employs a meticulous process to ensure that each garment meets the highest standards. Omniteksas approaches cutting with the goal of minimizing waste and promoting sustainability.

Let’s review the process

Once the fabrics undergo knitting, dyeing, finishing and rigorous quality checks, they are delivered to Omniteksas’ cutting bar. At this stage, the choice between manual and automatic cutting is crucial and is based on the specific properties of the material.

Automatic Cutting Efficiency:

Omniteksas employs advanced automatic cutting machine to enhance efficiency. With a single machine capable of cutting multiple pieces simultaneously, the focus shifts to arranging the patterns strategically to minimize waste. This not only optimizes resources but also contributes to the company’s commitment to sustainability.

Waste Reduction and Recycling: Wool and Cotton

In the case of wool and cotton, Omniteksas takes a proactive approach to waste management. Wool and cotton waste is collected and added to the recycling process, showcasing the company’s dedication to minimizing environmental impact. On average, Omniteksas adds a commendable amount of wool and cotton waste to recycling annually, further emphasizing their commitment to responsible manufacturing.

Waste Reduction and Recycling: Circular economy

Interlaced sections have potential that can be used in the creation of unique garments that are just as quality made as any other product, yet possess a statement of sustainability and enable the circular economy. There are endless possibilities while creating from what used to be considered fabric waste – from kidswear to limited collections of leisure wear.

Challenges and Solutions:

While the recycling of wool and cotton waste is well-established, other waste streams pose challenges. However, Omniteksas remains proactive in its pursuit of sustainability. The company places a significant emphasis on efficient resource utilization to offset the limitations in waste management technologies. This commitment is a testament to Omniteksas’ dedication to sustainability in the face of evolving industry challenges.

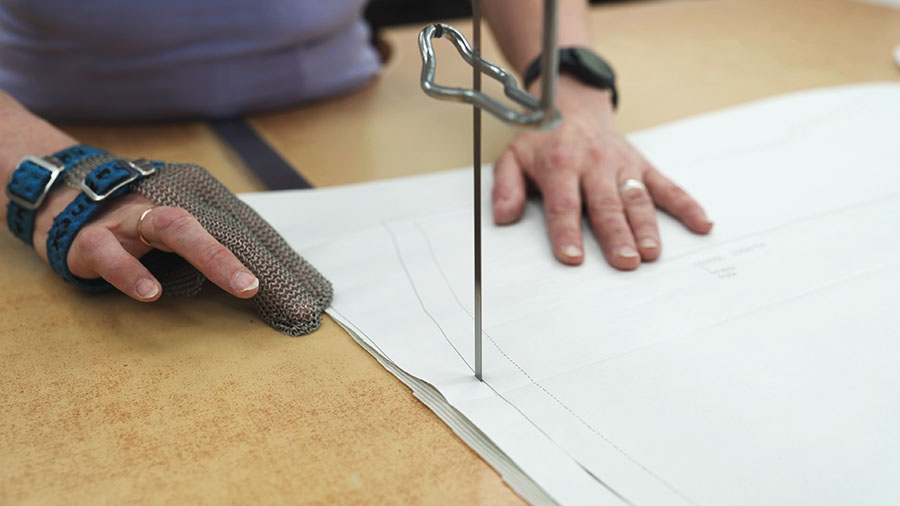

Manual Cutting Expertise:

In cases where fabric properties demand precision beyond the capabilities of automatic cutting, Omniteksas turns to manual cutting. Stretchy knitted fabrics, in particular, require a delicate touch due to their elastic and dynamic nature. Highly skilled employees with years of experience play a crucial role in mastering the art of cutting knitwear. In rare cases automation is not always a one-size-fits-all solution and in such situations manual cutting is performed, but Omniteksas tries to perfect the automatisation of this process as much as possible.

Holistic art of textiles

Omniteksas’ commitment to efficiency and sustainability sets it apart in the competitive world of garment manufacturing. By leveraging advanced technology for automatic cutting, responsibly managing waste, and valuing the expertise of their manual cutting artisans, Omniteksas embodies a holistic approach to textile production. As the industry evolves, Omniteksas remains at the forefront, embracing innovation while staying true to its core values of quality, efficiency, and sustainability.

Let’s craft exceptional clothing experiences!

Experience the advantages of vertical integration with Omniteksas, where we seamlessly convert yarn into ready-to-wear garments. Our one-stop production facility enables us to offer partners a full production cycle, ensuring a quick and change-responsive process.

Gintare

patapaviciene

Head of Sales